PVD stands for Physical Vapor Deposition, and is a finishing process conducted in a high-tech vacuum chamber utilizing precious metals such as Titanium, and an energized high temperature gas called a Plasma. It results in a hard, long-lasting surface that’s resistant to attack by many household chemicals, and completely immune to metallic corrosion making it the near-ideal finish for bathroom and kitchen fixtures.

Historically, brass and other decorative finishes were sprayed with a clear lacquer to ward off tarnishing. In many cases, this clear-coat was no match for daily household use. Once the lacquer wore away or simply failed, the exposed brass turned brown from oxidation, oftentimes in a very random and inconsistent manner. There is no method to repair damaged lacquer or tarnished brass in the field.

All of these problems ceased to occur with the advent of PVD. Suddenly, there was a new and improved brass that withstood punishment like chrome, providing a rugged shield for the underlying brass…durable, care-free, and low-maintenance!

PVD Vacuum Chamber

PVD Vacuum Chamber

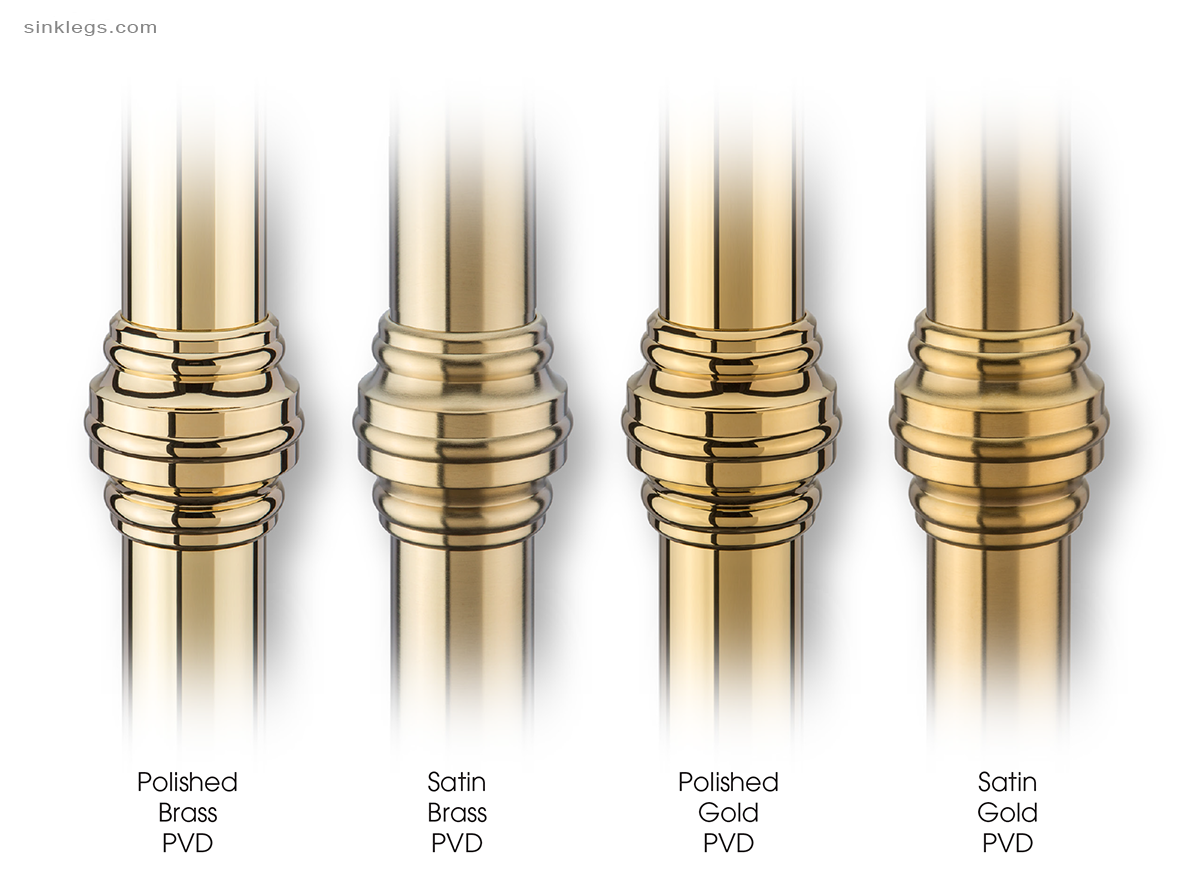

The PVD process involves many intricate steps. First the brass is highly polished to a mirror finish. It is then nickel plated, followed by a plating of chromium. Finally, it is PVD coated in a specialized and extremely intricate vacuum chamber. During the PVD process metallic atoms bombard the brass component, reacting with Nitrogen in the chamber, and forming a hard ceramic compound on the surface of the part. But…it’s not just on the surface like paint or plating; it’s metallurgically bonded. The old surface is replaced with a new surface that replicates the true color of brass (or gold…or bronze), which is extremely hard and resists many cleaners and acids, and is tarnish-free.

Unlike small, easily-handled faucet components, Palmer’s tubular parts are quite long and unwieldy, requiring extensive preparation labor and special fixtures to hold these components throughout the various PVD finishing procedures. A typical 2-leg or 3-leg system consists of forty to sixty individual components and tubes…quite a lot…all of which require jewelry-like preparation. This translates to a much higher cost for PVD coatings on Palmer legs and shelf systems compared to our conventional finishes…quite often twice the cost or more. Nevertheless, PVD finishes are a good investment if you want your metalwork to look fantastic for many years to come.

for more information see: PVD Process

I have a concern with the finishes. I would be purchasing the nickel finish, but is it real nickel.

Thanks

Our polished and satin nickel finishes are a heavy plating of elemental Nickel onto solid brass tubing and components.